The art of garment dyeing is an ancient one. There is evidence that prehistoric man applied colored pigments to vegetable & animal matter such as fibers & skins. Garments made from various fabrics are now being dyed & delivered to the customer in a short period of time.

With today’s exploding clothing markets of casual & sportswear, garment dyeing has emerged as one of the better production routes towards meeting the quickly changing demands of the fashion market.

Though any kind of material can be dyed in a garment but cotton is more popular to dye and finishes in garment form than any other fiber. Processing of DENIM and some CHINOS is more common fashion in garment dyeing field.

VARIOUS TECHNIQUES OF WASHING & FINISHING:

Denim goods finishing has a longer history, the techniques used for denim finishing has been extended to other items such as chambrays, solid color indigo dyed fabrics & chinos suiting.

A variety of washing effects are achievable on denim goods dyed with the traditional indigo dyed, which is selected on accounts of its brilliant blue color & excellent fading characteristics to washing, finishing or abrasion.

Depending upon the dyeing method, goods dyed with indigo dyes have poor color penetration with ring dyed yarns; thus after finishing them, they give a good acceptable faded look.

Some of the most popular common & advanced washing & finishing techniques for denim garments & others are given below.

CONVENTIONAL WASHING :

This entails designing the materials with enzyme & detergent followed by washing at an elevated temperature. The degree of color fading is comparatively slight, but uniform.

STONE WASHING :

Volcanic rocks also called as PUMICE stones are added to the garments during washing as the abradant.

Colour fading by this process is more but not uniform. The degree of color fading depends upon washing time and stone ratio (i.e. Wt. of stones: Wt. of Garments), size of stones, liquor ratio & garment load.

Generally, the washing machine is run for 60 min. to 120 min. & it depends upon the degree of fading.

DENIM BLEACHING :

In this process, a strong oxidative bleach such as Sodium hypochlorite or Potassium permanganate is added during washing, with or without stone addition.

The discoloration is usually more apparent depending on the strength of the bleaches, liquor quantity and treatment time.

A strong bleach with short treatment time is preferred for better-bleached colors. The bleached goods should be adequately anticlored or after washed with peroxide to minimize subsequently yellowing & tendering of the goods.

Some times optical brightening agent is added to get a brighter appearance for white or near white shades.

A recent innovation in decolorizing Indigo referred to as enzyme bleaching using LACCASE enzyme(Mediator system). Laccase is an Oxidoreductase enzyme that accepts oxygen from air & attaches it to a mediator, which then reacts & decolorizes the indigo molecule.

The mediator, which is an organic molecule, consumed during 10 – 20 min. period so the process is self-limiting without any degradation or weakening of the product or no danger of over bleaching.

Color can also be removed in denim washing by reductive processes. One process, some times called Sugar bleaching, uses carbohydrates like Dextrose, which contain reducing groups.

The process requires high pH, elevated temperature & large quantity of Carbohydrates. The use of a high level of Carbohydrates produces wastewater & high BOD & COD.

ACID WASHING ( STONE WASH) :

Acid washing is usually done by tumble drying the garments with Pumice stones presoaked in a solution of Sodium hypochlorite (5 – 10%) or potassium permanganate (3 – 6%) such that localized bleaching takes place resulting in a non-uniform sharp Blue/ White contrast.

The color contrast after tumbling can be further enhanced by a subsequent optical brightening. Soft stones that are usually dust off are suitable for this process.

Now It’s Your Turn!

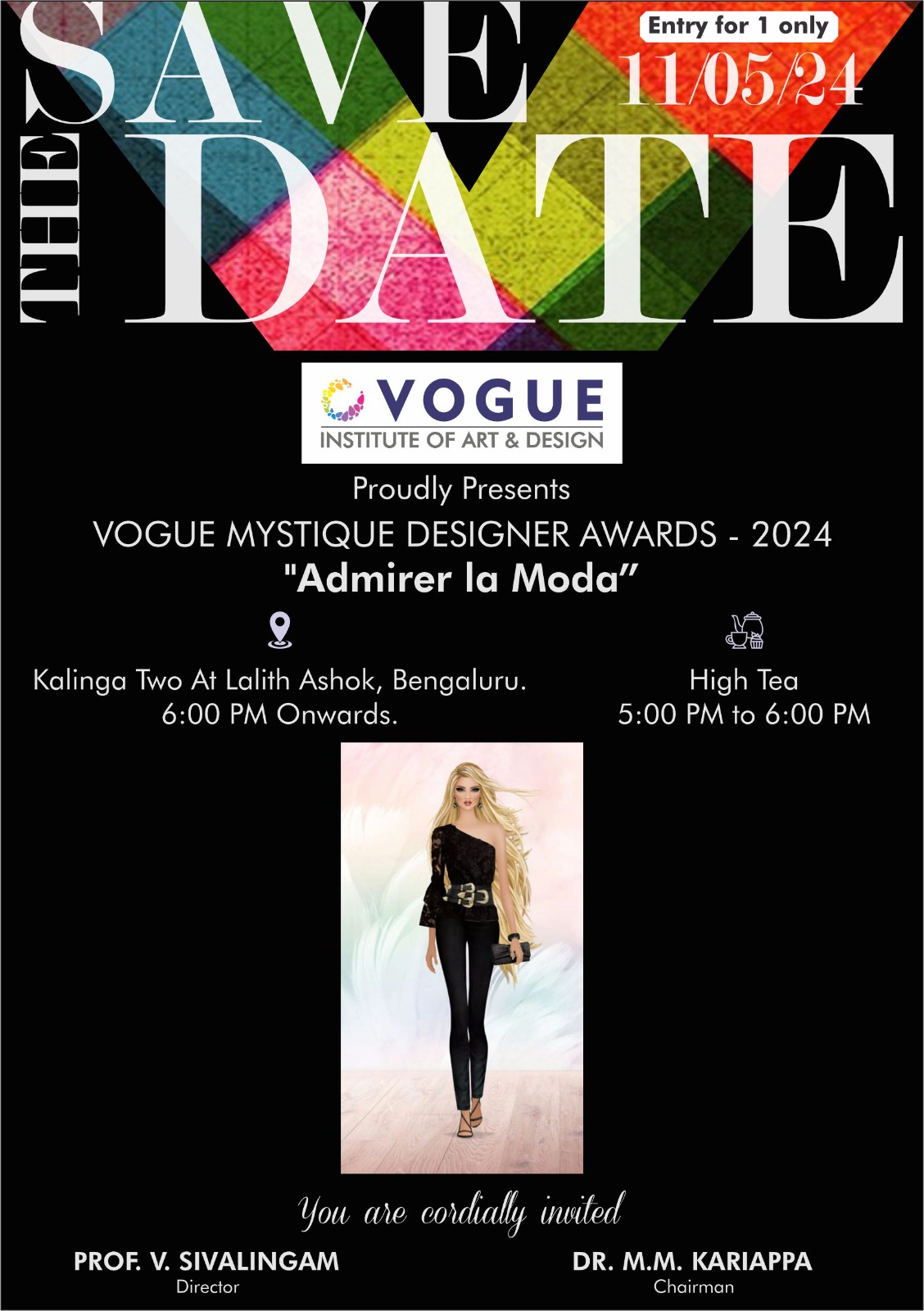

Do you wish to create designs for woven, printed fabrics or surface ornamented fabrics? At Vogue Fashion Institute, we offer Textile Design Courses to help students get the practical knowledge required to shape their career in textile designing.