In enzyme finishing, Cellulase/ Amylase enzymes are used. The single component CELLULASE enzyme, alkaline-neutral cellulose, was introduced in 1992. This mono-component enzyme produced high – contrast abrasion & gave very good fabric strength retention.

Hydrolysis of the cellulose, which is catalyzed by an enzyme, causes the surface fibers to become weakening & later removed when subjected to fabric to fabric abrasion or fabric to pumice stone abrasion during the washing. The temperature & pH used is dependants upon the enzyme used. Usually, neutral cellulose (2 – 4 GPL) are applied at pH of 6-7.

PEACH SKIN FINISHING USING ENZYMES :

Peach skin finishes are given to Chino’s suiting materials, Denim material and for Tencel fabrics. Tencel has high strength ( In dry & wet state) & dry tenacity is almost equal to that of Polyester.

According to Mr. Rodgers production of the Peach – skin effect requires that the fiber be PREFIBRILLATED, DEFIBRILLATED & REFIBRILATED.

Prefibrillation splits the surface hairs on the fabric similar to stripping back the bark on a twig. It requires mechanical action also such as tumbling in a wet processing stage. Prefibrillation creates tangled masses of fibers.

Defibrillation of the pills of fiber (Entangled mass of fibers) with enzyme produces a very smooth fabric with almost no protruding fibers. Any of the acidic, mildly acidic or neutral cellulose enzymes are suitable for defibrillation.

Refibrillation or secondary fibrillation produces SECONDARY HAIRS on the fabric surface, generating the peach skin hair.

Prefibrillation is carried out in the desizing stage. Defibrillation takes place in the washing stage & for Denim garments the same process is used for color washing also. Refibrillation is accomplished by agitation in the normal softener application stage of wet processing.

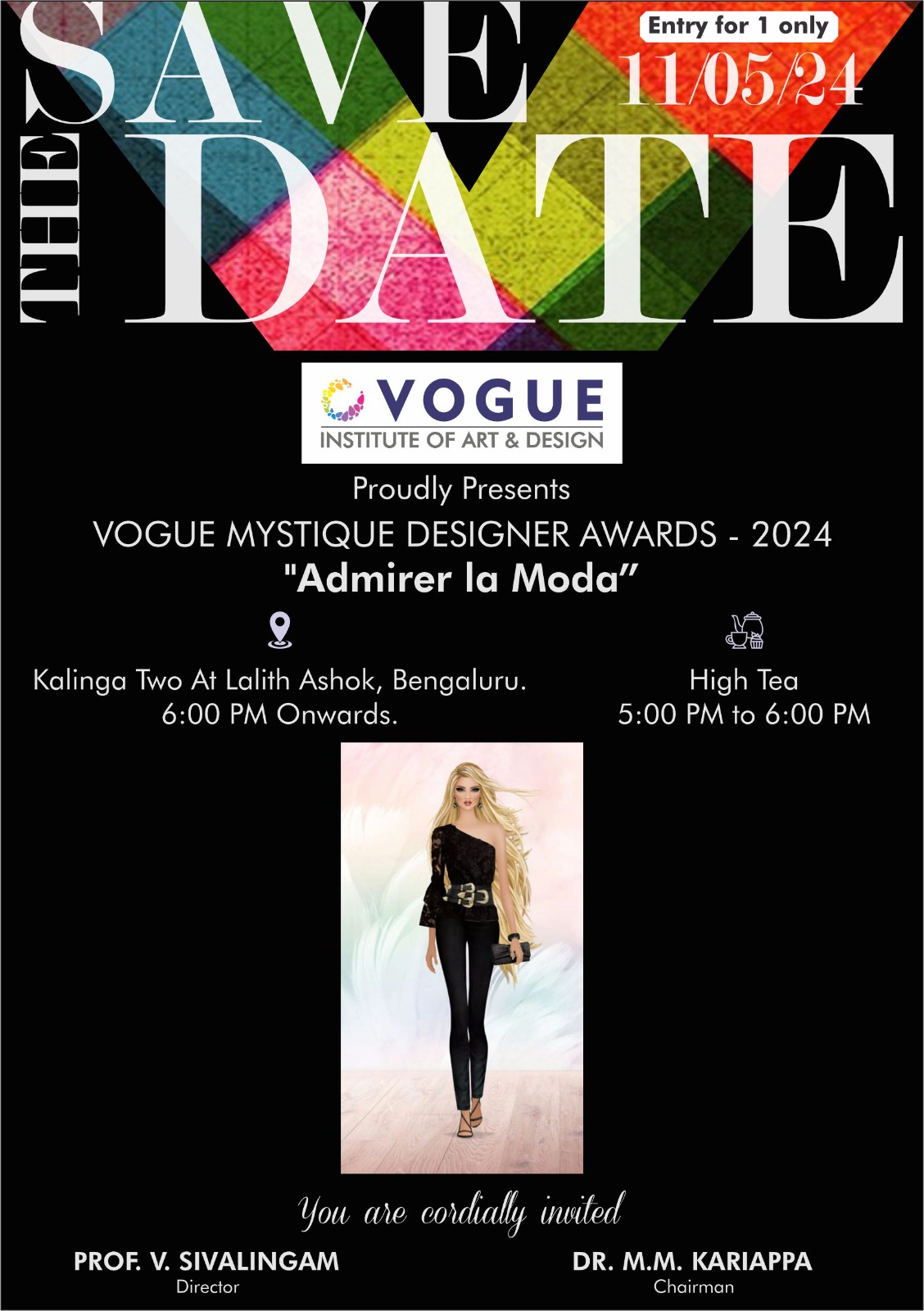

Are you ready to join?

Join us in this exciting career and get the most out of it with a degree in Textile Designing Courses offered by Vogue Fashion Institute.